Add My Company

Add My Company

3D scanning plays a crucial role in the start and finish of 3D fabrication processes. Whether referencing the precise shape of the human body, digitising hand-sculpted clay designs, or incorporating existing designs via reverse engineering, 3D scanners are a quicker and more effective way for engineers, product designers, and researchers to begin building digital models.

A 3D scan of a deformed part can tell you where to reinforce the design in the next revision. Similarly, after the part has been used, a scanner can show how it is performed and support quality control and help verify the accuracy of a 3D printed part.

The best 3D scanning system for your application and budget can be hard to choose with so many different options available, ranging from desktop to handheld scanners. In this article, we highlight some of the most significant steps to take into account when choosing a 3D scanner.

How Does 3D Scanning Work in 3D Printing?

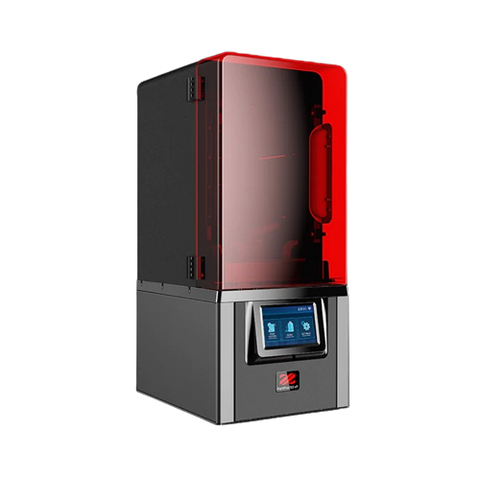

By extending the functionality of SLA 3D printer, a 3D scanner lets you duplicate nearly any object's shape. Combining the two technologies yields a potent digital workflow that can streamline and refine procedures across several industries.

A mesh of triangles that represents an object's surface at actual scale is what is produced by a 3D scanner. In some circumstances, object replication can be done directly from the scan without the need for CAD work. Combining scanned 3D models with solid CAD models can yield a powerful hybrid workflow.

Customised ergonomics, for instance, incorporate mechanical design elements with the physical imprint of a human body part. This guide will help you find the perfect 3D scanner for all your printing needs.

Customised ergonomics, for instance, incorporate mechanical design elements with the physical imprint of a human body part. This guide will help you find the perfect 3D scanner for all your printing needs.

What to Consider When Choosing a 3D Printer?

1.Needs - It is essential to dig deeper into specifications, define your scanning goals and know the object size before anything else. Knowing about these questions will guide your search and help you in a better way.

2. Technology - There are two types of technology to dominate the market like structured light scanners and photogrammetry systems. Structured light scanners project patterns capture deformations and offer high accuracy at a cost. While photogrammetry uses multiple photos to create a 3D model which is budget -friendly.

3.Accuracy - Aim to choose a scanner with an accuracy of 0.1 mm and a resolution capable of capturing fine features. Higher resolution often converts to big enough size with some processing time.

4.Scan volume - Check the maximum size you’ll scan. Only photogrammetry offers flexibility in scan volume but struggle in scan volume with intricate details on large objects.

5.Software - Check if the scanner’s software perfectly integrates with your preferred 3D modelling and slicing software. Compatibility allows for a workflow from scan to print.

6. Budget - 3D scanners are available in the range of photogrammetry setups to high -end structured light system. You must determine your budget and look for features that align with your needs.

In Conclusion,

Industry-wide digital workflows require the use of 3D printers and scanners. To learn more about how to use 3D scanning to enhance part design and production, choose a service provide that can help you progress in your industry. you can also discover how to combine 3D printing and 3D scanning to enhance a range of workflows in engineering, product design, and other areas.

Learn about the cutting-edge 3D printing technology from EVO 3D and experience stereolithography (SLA) and selective laser sintering (SLS) firsthand by choosing our onsite training partner 3D 360. So, just embark on your 3D printing journey and explore our onsite training now.

For more information on Tips to Choose the Best 3D Scanner to Use with Your 3D Printer talk to Evo3D