Add My Company

Add My Company

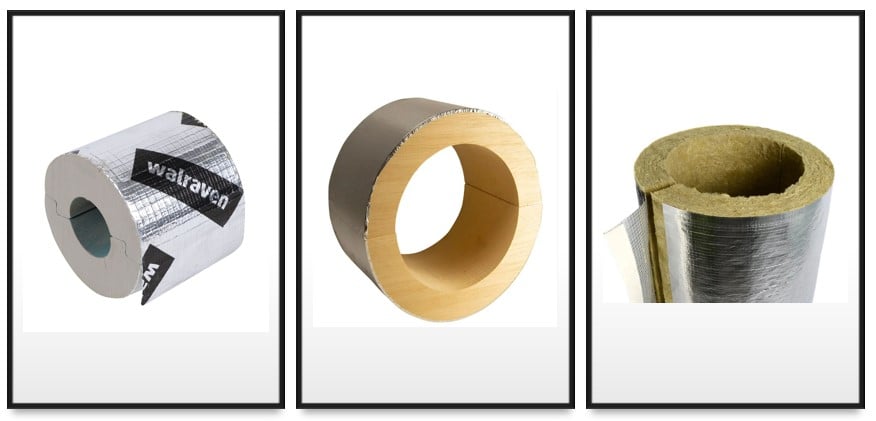

Phenolic insulated pipe supports are often considered a favourable choice compared to wood and mineral wool. This is because they tend to offer the best all round solution as well as being cost-effective. Here’s a summary of how phenolic, wood blocks and mineral wool compare.

Thermal Insulation

Phenolic foam used in insulated pipe supports has excellent thermal insulation properties. It has low thermal conductivity, which helps minimize heat transfer between the pipe and its surroundings. This reduces energy loss, improves energy efficiency, and maintains the desired temperature of the fluid being transported. Wood is considerably less thermally efficient and does not provide a vapour barrier. Compared to mineral wool, phenolic foam generally has better thermal insulation properties and has a lower thermal conductivity, meaning it minimizes heat transfer more effectively.

Moisture Resistance

Phenolic insulated pipe supports are resistant to moisture and water. They do not absorb moisture like wood, which can lead to degradation, rotting, or warping over time. Mineral wool, although it provides insulation, can absorb and retain moisture, potentially compromising its thermal performance.

Dimensional Stability

Phenolic pipe supports have superior dimensional stability compared to wood and mineral wool. They do not warp, deform, or change shape significantly due to temperature or humidity variations. This ensures consistent support, alignment, and load distribution for the pipes.

Fire Resistance

Phenolic foam is known for its good fire-resistant properties. It has a high ignition temperature and low flame spread characteristics. Walraven’s Phenblox® has a densely cross-linked structure that makes it difficult to ignite when subjected to fire. It has achieved a European Reaction to Fire rating of Class BL-S1,d0. Wood is obviously a very flammable substance and mineral wool is simply classified as non-combustible.

Chemical Resistance

Phenolic foam exhibits good chemical resistance, making it suitable for environments where pipes may come into contact with corrosive substances or chemicals. Wood can be susceptible to chemical degradation, while mineral wool’s resistance to chemicals may vary depending on the specific substances.

Longevity and Durability

Phenolic insulated pipe supports have a longer lifespan compared to wood and may offer better durability than mineral wool. Phenolic foam is less prone to degradation, rotting, or deterioration over time, ensuring the longevity and performance of the pipe supports.

Lightweight

Phenolic pipe supports are generally lighter than wood, simplifying handling, transportation, and installation. This can result in cost savings and improved efficiency during construction projects.

So which is the best choice?

It is clear that phenolic insulated pipe supports offer a robust and effective solution for the majority of circumstances. Wood blocks offer a significantly inferior performance and are no longer recommended according to the British Standard BS5970:2012. Mineral wool blocks are fairly new to the market and can be expensive. Their overall performance may not be as robust as phenolic but they do offer a completely non-combustible solution – if this is required. In most construction projects a Euroclass fire rating such as that which phenolic offers, is sufficient. You should always check individual project and specification requirements to determine the right solution for your project.

Follow the link below to take a look at Walraven’s phenolic pipe supports, or if you have any questions, get in touch with our Technical Team here.

For more information on How does phenolic block compare to wood and mineral wool? talk to Walraven Ltd