Add My Company

Add My Company

ENVIRONMENTAL PRODUCT DECLARATION (EPD)

Climate change is no longer a distant threat, and its impact is being felt around the world, including the UK. The construction industry, a major contributor to greenhouse gas emissions and resource consumption, is undergoing a crucial shift towards sustainability.

UK businesses are recognising the urgency of adopting greener practices for several reasons. The UK government aims to reduce all direct emissions from public sector buildings by 50% and 75% by 2032 and 2037 respectively, against a 2017 baseline. All UK emissions are to reach net zero by 2050 [1].

Businesses that fail to adapt, risk falling behind new regulations and missing out on potential opportunities. Recently, fines had been issued for breaches of climate change schemes which are in place to help ensure the UK reaches its target of net zero emissions by 2050. More than 30 companies have been issued with fines by the Environment Agency as part of efforts to reduce greenhouse gas emissions [2].

Investors and consumers are increasingly prioritising environmentally responsible companies. A focus on sustainability can enhance brand reputation and attract investment.

Sustainable practices often lead to resource efficiency, reducing waste and lowering operational costs. But how are customers in construction able to identify products that are sustainable? Read on.

WHAT IS AN ENVIRONMENTAL PRODUCT DECLARATION (EPD)?

An Environmental Product Declaration (EPD) acts like a report card for a building product's environmental impact throughout its entire lifecycle.

Any product can potentially have an EPD, including building materials like concrete, steel, or insulation, but also everyday items like furniture, electronics, or clothing. The key is that the EPD provides a transparent assessment of the product's environmental impact across its entire lifespan.

The EPD is generated on data obtained through a life cycle assessment (LCA).

An LCA is performed using a peer-reviewed Product Category Rules document (PCR) in line with the European standard EN 15804, ISO 14025, and other related international standards.

EPDS are not yet compulsory in the UK, but the market is increasingly self-regulating as manufacturers seek to demonstrate carbon transparency and market their products accordingly.

EPD STANDARDS AND RULES

EPDs follow international standards (ISO 14025) and undergo independent verification, ensuring data credibility and transparency. They are typically valid for five years.

Every EPD is created using a set of product category rules (PCR) that allow for fair comparisons between similar products. This allows construction companies to make informed choices on the products they’ll use based on environmental performance.

So, how are EPDs created?

EPDs are created through a specific process for a particular product by its manufacturer or a third-party organisation.

EPDS WITHIN THE CONSTRUCTION INDUSTRY

The construction industry is a major contributor to environmental impact, contributing around 37% of greenhouse gas emissions [3] With this in mind the upcoming revision of the Construction Products Regulation (CPR) signifies a major step towards increased transparency in the environmental impact of construction materials.

This revision, incorporating the acquis of the regulation, will mandate the eventual integration of environmental declarations, such as Environmental Product Declarations (EPDs), into the Declaration of Performance (DoP) for construction products across Europe.

This integration process is expected to begin in mid-2026, with a focus on the Global Warming Potential indicator as outlined in the EN 15804+A2 Product Category Rules (PCR). This initial phase paves the way for the inclusion of a broader range of environmental impact indicators in the future.

CLOCKWORK SCREED & SUSTAINABILITY

What does an EPD have to do with us at Clockwork Screed you might wonder. We use building materials such as liquid poured screed and poured insulation. A lot of the contracts we hold have a sustainability remit and want to know how we can help fit into their net zero carbon goals.

We use poured insulation, two options; energystore TLA® which combines eps beads coated in an innovative additive with cement to create a pourable insulation. This unique poured insulation offers a noncombustible alternative for use in floor and roof construction as a high strength void former or insulation.

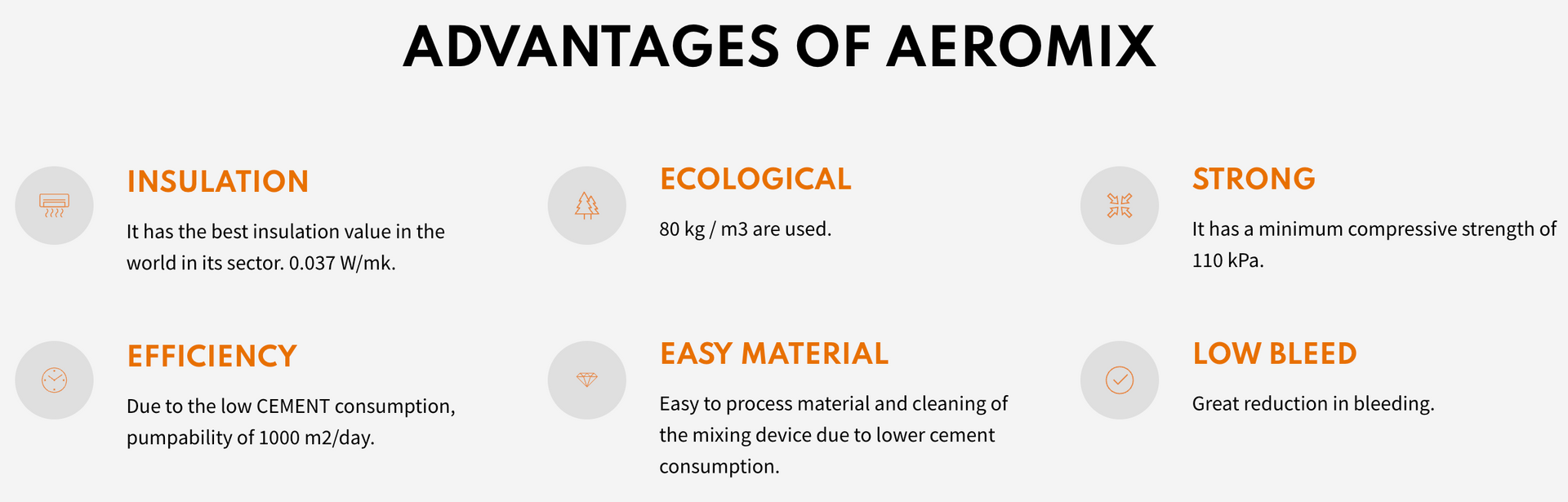

We also offer Aeromix. Aeromix is an award-winning product that blends concrete with polystyrene to create insulation in ground floor flooring. The product has one of the best insulation values in the world and is also known for its low carbon footprint.

Aeromix represents the latest technology and is world’s leading EPS flowing insulation 0.037 W/mk.

Contractors favour using Aeromix for their projects due to its incredible thermal properties (it has the best insulation value in the world in its sector at 0.037 W/mk); high strength; ease of pour and efficiency; and strong environmentally friendly credentials.

PARTNER WITH CLOCKWORK SCREED

We are an experienced screed installer based in Stockport, but cover all areas in the Northwest of England. The services we offer include:

Liquid Screeding Installation- Aeromix Poured Insulation & Installation

For all of your poured insulation and screeding needs, get in touch with us today.

READY TO DISCUSS YOUR NEXT SCREEDING PROJECT?

SOURCES

For more information on ENVIRONMENTAL PRODUCT DECLARATION (EPD) talk to Clockwork Screed Ltd