Add My Company

Add My Company

Why are Rate of Change Alarms used?

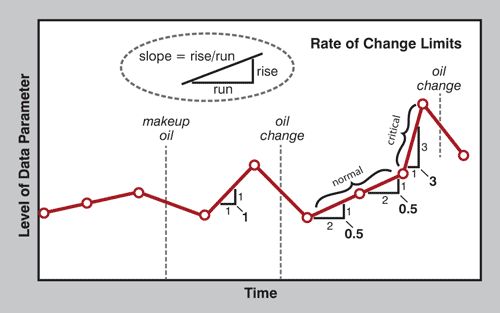

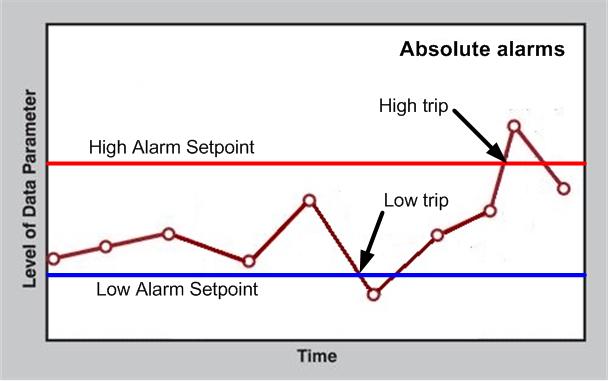

Rate of change alarms are used to predict an event that is abnormal behaviour for a system or process. The objective being in order to take preventative action in order to avoid system or process failure or damage. If a process value suddenly increases at a rate beyond the normal, then it indicates something unusual has changed in the system or process. This is different to an absolute (low or high) alarm.

Rate of Change can be an Increasing Rate(+) or Decreasing Rate(-). Using Rate of Change Alarms also means you need to understand your process dynamics very well. You are taking expert knowledge and implementing it to safeguard your plant in the absence of the expert.

Absolute Alarms vs Rate of Change Alarm

Rate of change alarms differ from normal (level) alarms in that they respond to a specified rate of signal change rather than to the crossing of an absolute threshold in the measured variable.

Where would Rate of Change alarms be used?

A good example is a process variable that may or may not have a fixed alarm point but we need to predict when the trajectory of the process is going the harm the smooth running of the process or to prevent catastrophic failure and damage. We also know that often physical process parameters over-shoot the desired limits hence the use of process controllers using PID to manage this. However, in failure mode a process can still cause damage if the controller cannot respond to manage the process. Rate of change alarms will kick in only when the normal rate-of-change is exceeded. This pre-supposes that normal rate of change is determined for a given process or system often by an expert with intimate knowledge of the system.

Some Examples

1. A reservoir that is emptying too quickly may need to trigger additional pumps into action to refill the reservoir. We are predicting the low level before it happens and take corrective action before the low-level alarm does.

2. A sudden increase of levels of a contaminant in a system may need to trigger servicing of the system. We predict the high level of contaminants before they can cause damage, e.g. Gearbox oil contamination triggers a shorter service interval alert pre-empting maintenance.

3. Rapid Rate of temperature increase may indicate imminent damage or catastrophic failure before normal alarm limits are reached. Corrective action is taken before alarm limits are reached perhaps preventing motor winding damage.

Often the domain of the control and safety programs, Rate of Change alarms can be implemented in hardware. A Rate of Change alarm has the advantage of adding an additional layer of protection to systems or processes. The Omniterm TTT from Omniflex with Rate of Change Alarms option provides just such additional layer of plant protection. Click here to read more about the Omniflex TTT.

For more information on Why are Rate of Change Alarms used? talk to Omniflex UK Limited