Add My Company

Add My Company

How To Improve Row Airflow Management

Ways to Improve Row Airflow Management in Data Centres

Aisle Containment the Essential Method To Improve Row Airflow Management

Row Airflow Management is the third step in improving Data Centre Airflow Management.

Firstly, ensure a hot-aisle-cold-aisle layout is utilised to improve Raised Floor Airflow Management. Place floor grilles only in cold aisles, replacing them with solid tiles or fitting them with grille covers elsewhere. Finally, seal openings in the raised floor using floor grommets. For instance, KoldLok Raised Floor Grommets being the leading solution for this purpose.

Implementing Rack Airflow Management

To implement Rack Airflow Management, seal openings in and around the rack. Use Blanking Panels to seal unused rack space within the mounting frame. EDP offers leading tool-free panels from EziBlank and HotLok.

EziBlank Blanking Panels are 6U sheets that can be easily resized at 1U intervals by bending the panel sheet at the required 1U score line. HotLok Blanking Panels come in 1U or 2U sizes and feature integral finger grips for improved handling, as well as cantilevered sealing vanes for a touch-tight seal against equipment or other panels.

Subsequently, it is important to seal gaps between the mounting frame and side panels, under racks, and between adjoining racks. RackSEAL Air Barrier, an expanded foam tape, provides the ideal solution for sealing gaps up to 120mm. AisleLok Under Rack Gap Panels, a self-adhesive or magnetic flexible membrane that can be adjusted for the required gap, serves as an alternative solution for sealing gaps under racks. Furthermore, larger air barriers can be used to seal bigger gaps within a row of racks where racks have been removed or where a building support column exists.

AisleLok Adjustable Rack Gap Infill Panels attaches magnetically to the side of a rack and pulls out to close the gap by attaching to the next rack. EziBlank Wall is a triangular rack replacement wall with different widths on each side, specifically for popular rack widths. This structure can be rotated to the size of the missing rack and easily slid into place. Most adopters to this solution find a typical payback within two weeks, while some Data Centres have experienced payback within 24 hours!

Steps to Improve Row Airflow Management

The third step in the 4Rs of Airflow Management involves focusing on Row Airflow Management. Once adjustments have been made at the Raised Floor and Rack levels, it is crucial to target enhancements at the Row level. At this stage, it is especially important to ensure that hot and cold air-streams do not mix. This goal can be accomplished by installing an aisle containment system.

Aisle Containment separates either the cold aisle, Cold Aisle Containment, or the hot aisle, Hot Aisle Containment. Without an aisle containment system, hot exhaust air can circulate over the top of the racks or around the sides of the last rack in the row. As a result hot and cold air-streams mix. Subsequently, this mixing can result in inefficient cooling or the formation of hot spots.

- Latent Cooling – Occurs when hot and cold air mix on the return path to the cooling units, resulting in reduced cooling capacity. This process can also lead to reduced levels of humidity, requiring the need for humidification to balance the moisture levels.

- Hot Spots – These are created when hot air enters the cold aisle, causing temperatures to rise. Because of concentrated hot air in a specific area it can result in critically high temperatures. This warmed air may be drawn into air intakes, leading to increased equipment temperatures.

Aisle Containment Solutions

Aisle Containment improves cooling efficiency in Data Centres by physically segregating hot and cold air-streams at Row level. Benefits of Aisle Containment include:

- Increased Cooling Efficiency – Cooling systems are optimised by preventing the mixing of hot and cold air-streams. Consequently leading to increased cooling efficiency and energy efficiency gains.

- Improved Server Performance – Cooler operating temperatures within the cold aisle improve server performance and reliability.

- Extended Equipment Lifespan – Properly cooled equipment can extend its life expectancy.

- Cost Savings – Energy consumption is reduced, resulting in lower operating costs.

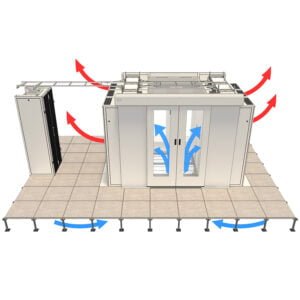

Cold Aisle Containment

In Cold Aisle Containment, enclose the cold aisle by filling gaps between racks with infill panels and spanning a roof across the entire cold aisle. This setup prevents the hot air from wrapping over the top of the racks and into the cold aisle. Aisle doors are added at the ends of the row to allow entry to the cold aisle. But, when closed, they prevent hot air from wrapping around the sides of the row. Cold air fills the aisle through floor grilles and is drawn through the IT equipment to effectively cool it.

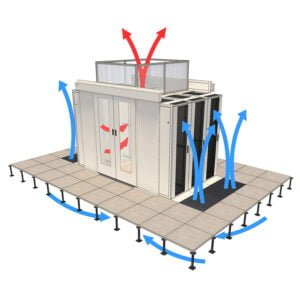

Hot Aisle Containment

Hot Aisle Containment involves enclosing the hot aisle. Infill panels should be used to fill gaps between racks, and doors should be installed at each end of the row. Unlike Cold Aisle Containment, instead of using a roof, panels are fitted between the top of the racks and the ceiling plenum. This configuration creates a chimney that guides the hot air emitted by the IT equipment into the ceiling plenum and back to the cooling units.

Aisle Containment Out-of-the-Box

AisleLok Modular Containment, from Upsite Technologies, is an out-of-the-box aisle containment solution that you can self-install in minutes. It provides many of the benefits of a traditional system. It consists of Rack Top Baffles that you can configure for use as either hot or cold aisle containment. Next, there are Adjustable Infill Rack Panels to seal gaps in the row. While, either bi-directional swing doors or sliding doors seal the end of the row. While this solution does not fully enclose either the hot or cold aisle. The baffles and doors drastically lower the effects of hot exhaust air wrapping over and around racks. This reduces the mixing of hot and cold air-streams, improving airflow management and enabling cooling optimisation opportunities.

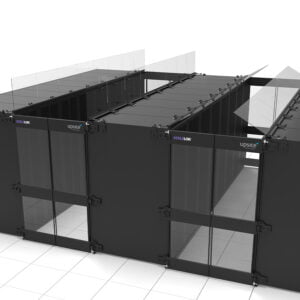

Bespoke, Custom Designed Aisle Containment Systems

EDP Data Centre Solutions designs, manufactures, and installs bespoke containment systems for use in retrofit, new build, and hyperscale projects. These systems are both scalable and modular and can be floor standing or suspended from the ceiling. The bespoke nature enables us to create custom-designed solutions. Infill panels seal around obstacles and eliminate gaps caused by differing rack heights. Additionally, we can maintain gaps for future rack expansion.

Furthermore, EDP aisle containment solution is rack independent and functions as a turn-key solution. We utilise high quality, reliable, synchronised sliding doors with hold open and soft close features. These doors open to the full width of the aisle, allowing for easier access. In our Cold Aisle Containment systems, we use FM Approved roof panels. We also offer data and power integration services, along with an in-aisle LED lighting system. Our solutions can be customised with branding and colour options, providing a fully bespoke solution.

Final Airflow Optimisation

After improving Raised Floor, Rack and Row airflow management, conduct the final part at room level. At this level, optimise cooling systems by raising temperature set points and adjusting variable fan speeds. These final steps in optimising cooling systems influence energy consumption, enabling cost savings to be made. Optimising cooling systems by reducing energy usage can result in cost savings.

Like more information on improving Data Centre Airflow Management? Need to discuss a requirement that could benefit from Aisle Containment, please contact us.

For more information on How To Improve Row Airflow Management talk to EDP Europe Limited