Add My Company

Add My Company

Blanking Panels – The Importance of Their Role in Data Centre Cooling

Blanking Panels play an important role in Data Centre cooling by aiding the improvement of rack airflow management. Improving Data Centre airflow management allows for the optimisation of cooling systems which enables energy efficiency gains to be achieved.

What is Airflow Management?

Cooling Data Centres requires the delivery of cold air to cool IT equipment. With increasing demands being placed on Data Centres ensuring that they are cooled efficiently has a huge impact on their energy efficiency. Cooling makes up a significant proportion of a Data Centre’s energy usage. So, optimising cooling to ensure CRAC units are operating as efficiently as possible, can make a big difference in reducing operational costs. To optimise cooling following Data Centre Airflow Management best practices is vital when looking to improve their efficiency.

There are three distinct areas in which to improve airflow management these are at Raised Floor, Rack and Row levels. Managing airflow management in these three areas was covered in the blog “Optimise Cooling by following Airflow Management best practices”.

The key component of good airflow management is preventing the mixing of hot and cold air streams.

Most Data Centres are laid out in a hot-aisle-cold-aisle layout. Cold aisles are supplied with cooled air to cool IT equipment, whereas hot aisles are filled with hot air being exhausted by the IT equipment. Preventing these two air streams from mixing removes issues such as hotspots, latent cooling and cooling unit incapacity.

The article “Implementing Data Center Cooling Best Practices” by Kevin Heslin of the Uptime Institute provides more insight into the steps required to follow cooling best practices.

The Importance of Blanking Panels

Blanking Panels help improve rack airflow management. They prevent preventing hot exhaust air from migrating from the back of server racks to the front, where it can mix with cold air that is cooling IT equipment. Blanking Panels help prevent hotspots. They also help reduce air intake temperatures that can be higher when no blanking panels are installed. This can help with the life expectancy of servers and other IT equipment.

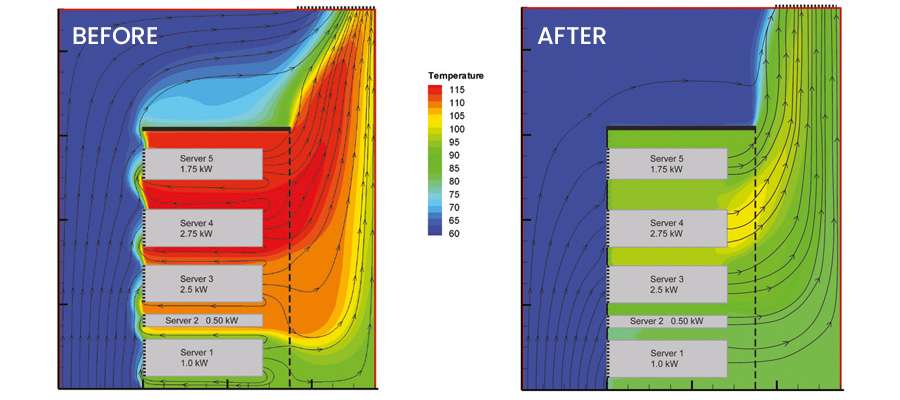

The image above shows the impact of installing HotLok blanking panels into a rack. The before image shows how hot exhaust air can circulate back to the front of the rack, resulting in air streams mixing and the generation of hotspots, particularly at the top of racks. Once installed hot exhaust air can no longer migrate out of the front of the rack, as a result it exhausts out of the back of the rack.

Blanking Panel Solutions

There are various blanking panel solutions on the market, with some solutions better than others. Metal panels typically require the use of fixings and tools to install them. However, tool-less panels such as HotLok or EziBlank provide a better solution. Both are quick and easy to install. HotLok are 1U or 2U panels that feature integral finger grips for easier handling. While cantilevered sealing vanes provide a touch tight fit to adjoining panels and IT equipment. EziBlank are 6U blanking panel sheets that are scored at 1U intervals. Allowing them to be easily resized to the required amount of blanking. Built-in in clips allow the panels to be easily clipped into position.

If cables are an issue and prevent a panel from being installed, then there is the EziBlank Brush Panel, a 1U brush blanking panel that reduces the opening while allowing cables to pass through.

When it comes to improving airflow management and optimising Data Centre cooling EDP can assist. From floor grommets to improve raised floor airflow management to bespoke aisle containment systems that improve row airflow management EDP has the experience and solutions to assist your facility.

To find out more how EDP Europe can assist you please contact us.

For more information on The Importance of Blanking Panels Blanking Panels talk to EDP Europe Limited